- 4,936 meters completed to date in 11 diamond drill holes in the Douay West, Main Porphyry and “20” zones of the Adam Creek Gold Deposit

- 2017 gold assay interval results include: 2.11 g/t gold over 20.6 meters (DO-16-147), 2.20 g/t gold over 23.1 meters (DO-16-149) and 3.53 g/t over 4.5 meters (DO-17-151)

- 2nd drill mobilized on site with plans to mobilize additional drills in coming weeks

Montreal, Quebec: Aurvista Gold Corporations (“Aurvista” or the “Company”) (TSX-V: AVA, OTCQB: ARVSF; Frankfurt: AV2) is pleased to update shareholders and stakeholders on the advancement of the 30,000 meters diamond drilling campaign from the Company’s Douay Gold Project (“Douay”).

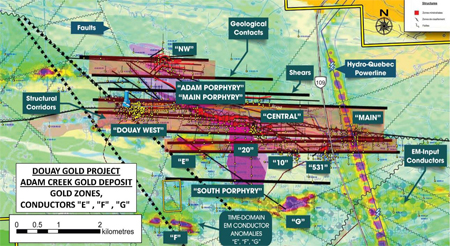

To date, some 4,936 meters have been drilled in 11 diamond drill holes (DO-16-147 to 149, and DO-17-150 to 157) in the Douay West, Main Porphyry and “20” zones of the Adam Creek Gold Deposit (the “Deposit”) (refer to appended Figure 1). Unfortunately, the sequencing of drill holes was set by warmer weather conditions which are unfavorable to drilling under wet conditions; drill holes with the easiest winter surface access were done first.

Keith Minty, COO of Aurvista, stated “Aurvista’s diamond drilling campaign is progressing on schedule with two core drills now on site. Plans are to accelerate the campaign as two new wood-cutting permits were issued for a total of 43 proposed drill holes. We will be adding more drills in the coming weeks to test the horizontal and vertical extensions of a number of targets: (1) the Main Porphyry Zone to the northwest towards the NW Zone, over a 1,200 meters strike length; as well as the area beyond the NW Zone for an additional 1,000 meters in strike length; (2) the Adam Porphyry Zone to the east and west-northwest, along an additional trend length of 1,000 meters; (3) the Central, “20” and “10” zones, and their potential connections along east-west mineralized structures and to the Main Porphyry zone, over a 1,500 meter length.”

Mr. Minty added “The objective of the first drill holes were to prove the new geological model by extending the known mineralization along east-west corridors in proximity to three known gold zones. A limited number of historical drill holes were twinned and new holes were drilled that visually extended the gold mineralization along the corridors and down-dip of previous intersections. The overall objective of the 30,000 meters drilling campaign is to outline additional higher grade mineralization in the range of 3 to 15 g/t gold and the lower grade in the 0.3 to 1.5 g/t gold, as well as increasing the size of several individual gold zones, which when combined could have an impact on increasing mineral resources at Douay.”

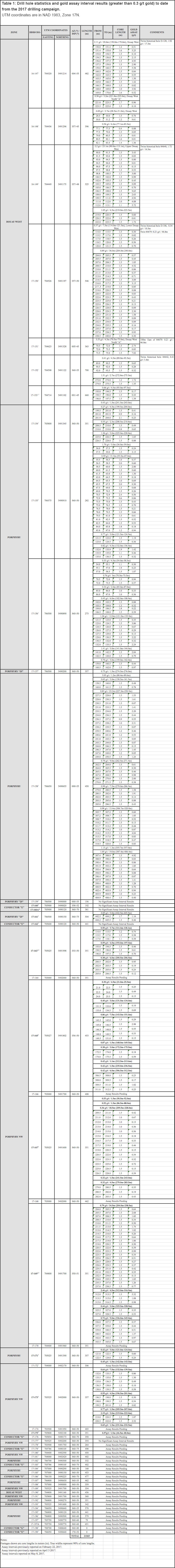

Gold assay interval results are available for the first six drill holes (DO-16-147 to 149, and DO-17-150 to 152) and are shown in the table below. The appended Table 1 summarizes all drill holes statistics and individual gold assays of the interval results.

Gold assay interval results received to date confirm predictability and reproducibility of assays, and continuity of gold mineralization from the historical holes as seen in the following table:

| DDH# | INTERVAL ASSAY RESULTS |

| DO-16-147 |

Twins historical hole: D-128, 1.92 g/t / 17.3m |

| DO-16-148 |

2017 |

| DO-16-149 |

Twins historical hole: 84640, 1.72 g/t / 16.3m |

| DO-17-150 |

Twins historical hole: D-106, 0.34 g/t / 10.5m |

| DO-17-151 |

100m East of 84679: 0.21 g/t / 46.8m |

| DO-17-152 |

Twins historical hole: 84642, 0.41 g/t /1.6m |

Note: Footages shown are core lengths in meters (m). True widths represent 90% of core lengths.

Significant gold mineralization was intersected in 3 holes: 2.11 g/t gold over 20.6 meters (DO-16-147), 2.20 g/t gold over 23.1 meters (DO-16-149) and 3.53 g/t over 4.5 meters (DO-17-151), all from the Douay West Zone.

In addition, the thorough drill core sampling of the 2017 drilling campaign has likely contributed to the identification of new gold mineralization in 4 of these 6 drill holes: 0.56 g/t over 6.4 meters (DO-16-148), 1.05 g/t over 4.5 meters (DO-16-149), 0.89 g/t over 36 meters (DO-17-150), and 0.41 g/t gold over 4.5 meters and 1.51 g/t over 2.7 meters (DO-17-152). This was also observed in 2016 during the re-logging and gold assaying of un-sampled mineralized zones from the historical drill core. The full 2016 gold assay and core re-logging program results will be made available later in the year once all compiled, validated and incorporated in the overall database.

The objective of proving the new geological model is being met; new results are extending the known mineralization along the east-west structural corridors and down-dip of previous intersections.

Quality Assurance (“QA”) and Quality Control (“QC”)

In 2016, Aurvista implemented strict Quality Assurance (“QA”) and Quality Control (“QC”) protocols at Douay covering the planning of and placing drill holes in the field; drilling and retrieving the NQ-sized drill core; drill hole surveying; core transport to the Douay Camp; core logging by qualified personnel; sampling and bagging of core for analysis; transport of core from site to the analytical laboratory; sample preparation for assaying; and analysis, recording and final statistical vetting of results. The complete description of protocols is appended.

Douay Gold Project and Company Profile

Aurvista Gold Corporation is a junior gold exploration and development Company with 131,912,407 shares outstanding trading on the TSX Venture Exchange in Canada, the Frankfurt Stock Exchange and OTCQB in the US. Aurvista’s asset is the Douay Gold Project, consisting of a 100% owned interest in 250 contiguous claims totaling 133.1 km2, plus a 90% interest in 5 contiguous claims totaling 0.2 km2 and a 75% interest (25% held by SOQUEM) in 32 contiguous claims totaling 11.9 km2. In total there are 287 claims covering 145.3 km2 located along a 20 km segment of the Casa Berardi Deformation Zone in the prolific Abitibi Belt of northern Quebec. Douay is located 40 km SW of the Matagami Base Metal Camp and 150 km N of the Val-d’Or-Malartic gold Camp (both in Quebec).

In August, 2012, Aurvista updated the Mineral Resources estimates that included 657 holes in more than 185,000 metres drilled on Douay since its discovery to the end of March 2012. Douay contains base case Mineral Resources of 2.7 million tonnes of Indicated Resources at 2.76 g/t gold for 238,000 ounces above a 0.3 g/t gold cut-off grade. Under a sensitivity analysis cut-off grade of 0.5 g/t gold, the Indicated Resources total 2.5 million tonnes grading 2.98 g/t gold for 235,500 ounces. There were additional base case Inferred Resources of 115 million tonnes at 0.75 g/t gold for 2.75 million ounces above a 0.3 g/t gold cut-off grade. Under a sensitivity analysis cut-off grade of 0.5 g/t gold, the Inferred Resources total 62 million tonnes grading 1.06 g/t gold for 2.1 million ounces. Details can be viewed on the Company’s website at www.aurvistagold.com.

Qualified Person

The technical contents in this news release have been approved by Mr. Jean Lafleur, M. Sc., P. Geo., President and CEO for Aurvista Gold Corporation, and Antoine Yassa, P. Geo., Database Manager for the Douay Gold Project. Both individuals are Qualified Persons under National Instrument 43-101.

For further information please contact:

|

Mr. Jean Lafleur, P. Geo. |

Mr. Keith C Minty, P. Eng., MBA |

NEITHER THE TSX VENTURE EXCHANGE NOR ITS REGULATION SERVICES PROVIDER (AS THAT TERM IS DEFINED IN THE POLICIES OF THE TSX VENTURE EXCHANGE) ACCEPTS RESPONSIBILITY FOR THE ADEQUACY OR ACCURACY OF THIS PRESS RELEASE.

Forward-Looking Statements

This news release may contain forward-looking statements based on assumptions, uncertainties and management’s best estimate of future events. Actual events or results could differ materially from the Company’s expectations and projections. Investors are cautioned that forward-looking statements involve risks and uncertainties. Accordingly, readers should not place undue reliance on forward-looking statements. When used herein, words such as “anticipate”, “will”, “intend” and similar expressions are intended to identify forward-looking statements. For a more detailed discussion of such risks and other factors that could cause actual results to differ materially from those expressed or implied by such forward-looking statements, refer to Aurvista Gold Corporation’s filings with Canadian securities regulators available on www.sedar.com or the Company’s website at www.aurvistagold.com.

Figure 1: Location map of the Adam Creek Gold Deposit from the Douay Gold Project outlining the principal gold zones - Douay West, NW, Central, the Porphyries (Adam Porphyry, Main Porphyry, South Porphyry), 10, 20, 531 and Main zones - and conductors E, F and G.

Table 1: Drill hole statistics and gold assay interval results to date from the 2017 drilling campaign. Note: UTM coordinates are in NAD 1983, Zone 17N

Quality Assurance (“QA”) and Quality Control (“QC”) Protocols

Drill holes positioning was pre-determined via interpretation on historical drill hole sections and level plans, based on the objectives of adding continuity to the known higher and lower grade gold mineralization at depth and on strike length, and to discover new gold mineralization. Both would have a significant positive impact on the potential of increasing the mineral resources at Douay.

Drilling is done along already established grids on pre-defined drill hole sections, ensuring appropriate drill hole spacing between holes and along parallel sections. Drill holes are positioned in the field following current established standards by azimuth orientation and dip with a hand-held or fixed GPS to ensure precision.

Originally, a single or multi-shot reflex orientation system was used in order to controls drill hole deviation, especially in areas of thicker overburden and magnetic rocks. A gyroscopic instrument is now recording continuous deviation of the drilled hole. Drill holes a few degrees to the left of the intended azimuth to ensure drill holes will follow the intended section.

Prior to and during drilling, the exact position of individual drill holes is verified by the Qualified Geologist in charge of the drill campaign. A down-the-hole deviation test is done once 9 meters has been drilled in bedrock, to ensure the drill hole has not deviated and it remains on course for its intended target depth. Assuming the results of the drill hole do not respect or conform to the technical parameters outlined prior to the drilling, or if the deviation has taken the drill hole outside the normal influence of the vertical section, the drill hole is re-started to ensure the target depth has been reached and explained.

Core boxes are brought to the Aurvista core logging and storage facility at the Douay Camp at the end of each shift by the drill contractor. The Qualified Geologist regularly examine the drill core at the drill rig during the day or night to determine if the proposed target has been intersected. The Qualified Geologist instructs the drillers and/or foreman to either continue the drilling or stop the hole.

At the completion of each drill hole, the overburden drill rods are left in place on instructions from the Qualified Geologist, and a numbered red cap is placed over the protruding drill rod. The numbered cap is usually accompanied by a 1.5-meter-long red metal spike topped by a red metal flag to indicate the location of the drill hole for future surface surveying.

Once core boxes have been received by Aurvista at their core facility, a Qualified Geologist or Technician arranges core boxes on the core facility floor or temporary tables in numeric order from box 1 upwards. Core boxes are then opened and footage blocks are properly checked with the appropriate footages and checked for continuity. The Qualified Technician calculates footages using a measuring tape, making sure the correct footage is written on each footage block, and the end footage for each box is noted on the core box. The Qualified Technician will identify and tag each box with an aluminum metal tag writing the drill hole number and from-to footages, and will measure the Rock Quality Designation or RQD of the drill core and record the rock quality numbers.

The Qualified Technician takes conductivity and magnetic susceptibility or MPP readings directly on the core at 50 centimeter intervals and record the measurements. X-Ray Fluorescence or XRF readings are also taken at 3 meter intervals by taking a 5-centimeter-long piece of core and placing it in the XRF analyser for a reading of the whole rock and trace elements geochemistry to help identify rock types and alteration patterns associated with metallic mineralization.

The Qualified Geologist describe the drill core the GEOTIC Logging system. While describing or logging the drill core, the Qualified Geologist marks for sampling core showing sign of metallic mineralization. The Qualified Geologist marks the drill core with a colored wax pencil (usually in red) the actual intervals to be sampled and these are identified with a perpendicular line at the start and at the end of the intervals.

The Qualified Geologist fill outs (with drill hole number and the from-to intervals for each sampled interval) an ALS Laboratory Group numbered dual sample tags and insert at the end of each interval to be sampled. Samples are taken at 1.5 meter intervals, however sample intervals are adjusted to respect lithological and/or mineralogical contacts and isolate narrow (<1.5m) veins or other structures that may yield higher grades. Once all sample intervals have been chosen, photos of the wet and dry core are taken, usually 4 boxes at a time bounded by a white rectangular legend inscribed with the drill hole number, box numbers, and from’s and to’s.

The Qualified Technician saws the core of the sample intervals in half, cut normal to the predominant foliation and being properly oriented with a cut-line marked by the Qualified Geologist to cut along. One half of the core is kept as a witness sample, the other half is to be analyzed. The half of the dual sample tag for each interval is stapled to the bottom of the core box at the end of each sampled intervals. One half of the sampled intervals is bagged and tagged with one of the dual sample tags from the ALS Laboratory Group. Individual sample bags are sealed and placed into shipping pails and/or nylon shipping bags, sealed and marked with the contents. The samples are delivered by Aurvista personnel in batches sent to the ALS Laboratory Group facility in Val-d’Or, Quebec, for processing, crushing, pulverizing and analysis.

For Quality Control, the Qualified Geologist and Qualified Technician prepare sample duplicates from a quarter split of the half-sampled core inserted approximately at every 20 samples. The method is to split ¼ core of the original sample leaving ½ core remaining as witness in the core box. The results are reconciled with other ½ core samples by averaging the two ¼ field duplicate split results - the average of the two ¼ splits should be the same as a sample of the same ½ core.

A blank sample is inserted every 20 samples – an ideal blank sample usually consists of a granite or gabbro that is known not to contain any metals. Purchased cobbles, barren of mineralization, are also used as blank material. A low-grade rock standard is inserted at every 100 samples. A high-grade rock standard is inserted at every 100. At the end of the analytical process, 5% to 10% of the sample pulps are re-analyzed by a different laboratory for comparative purposes. Multi-element major and trace element geochemistry is done at every 10 samples for rock type identification and alteration vectoring. Specific gravity is calculated in grams per cm3 is also calculated at every 5 or 10 sample intervals.